Tungsten Alloy Crucible Used in Sapphire Crystal

Basic Info

| Model NO. | w alloy |

| Transport Package | Standard Exported Plywood Case/Wooden Packing |

| Specification | As the customer need |

| Trademark | WMMP |

| Origin | China |

| HS Code | 8101999000 |

| Production Capacity | 50 Tons/Year |

Product Description

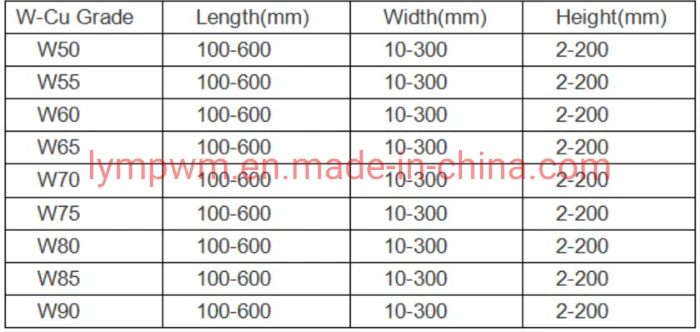

2022 Big Sale W50-W90% Wolfram Tungsten Copper Alloy SupplierProduct information:

Material: W50-90Cu10-50Brand:W55Cu45,W60Cu40,W70Cu30, W75Cu25, W80Cu20, W85Cu15, W90Cu10

Density: 11.85g/cm3-16.75g/cm3Product standard: GB8320-87WCu alloy rods size: dia(3.0-200mm)*LWCu alloy foil size: Thickness(0.08-0.7mm)*Width<120mm*Length<300mm

WCu Flatness tolerance:<4um

WCuRoughness:Ra1.6-Ra0.8

WCuSurface: polished, ground.

WCu alloy foil size: Thickness(0.08-0.7mm)*Width<120mm*Length<300mmWCu alloy sheet size see following attachment

WCu alloy rods size: diameter(3.0-200mm)*L<500mmWCu tungsten copper alloy application and performance:

1. Arcing contacts and vaccum contacts in high and medium voltage breakers or vaccum interruptors;2. Electrodes in electric spark erosion cutting machines;3. Electrodes for resistance welding;used where the combination of high heat resistance, high electrical

4. Some of the applications are in electric resistance welding, as electrical contacts, and as heat sinks.

5. As contact material the alloy is resistant to erosion by electric arc. WCu alloys are also used in electrodes for electrical discharge machining and electrochemical machining.

Advantages of Copper Tungsten Plates:

1. Better heat resistant;

2. Better ablate-resistant;

3. High intensity

4. High density;

5. Excellent thermal and electrical conductivity;

6. Easy to be machined.

Be relative to tungsten copper alloy,we also supply tungsten nickel copper/Iron alloy

High Quality Tungsten High Heavy Alloy ASTM B777-07 rods/sheet/tubes

Material:W90-97NiFe(Magnetic)&W90-97NiCu(Nonmagnetic)Density:16.8-18.8g/cm3

- High density (up to 65% denser than Lead).

- Denser materials exist (, pure Tungsten, Gold, platinum group metals) but their use is restricted by availability, workability and cost.

- Providing mass where volume space is limited.

- Concentrated weight essential where accuracy is required in placement of mass.

- Placement of weight in situations where airflow has a significant impact.

high grade Tungsten high heavy alloy AMST 21014 class 3(another expression)

- Material: W90-97NiFe(Magnetic) & W90-97NiCu(Nonmagnetic)

- Density:16.8-18.8g/cm3

- Rods Size:dia(1.5 -200) x Length<500mm Plate size: 0.1min Thickness*W*L

Property of tungsten alloy

AMST 21014 class 1

90%WNiFe, 90%WNiCu

Density : 17.0

Hardness: 32HRC max

Elongation: 5-20%

AMST 21014 class 2

92.5%WNiFe, 92.5%WNiCu

Density : 17.2

Hardness: 33HRC max

Elongation: 5-15%

AMST 21014 class 3

95%WNiFe, W95NiCu

Density : 18.0

Hardness: 34HRC max

Elongation: 3-10%

AMST 21014 class 4

97.5%WNiFe, W97.5NiCu

Density : 18.85

Hardness: 35HRC max

Elongation: 1-8%

The advantage of us:

1) We already have more than 11 years tungsten beads producing and exporting experience

2) Competitive price in the market,factory direct sales.

3) the whole production line from powder to finished products, top and steady quality assured

4) fast delivery and best after-sale service

5) Every month we export more beas to European,America,New Zealand,Korea etc