High Precision 5axis CNC Machining Stainless Steel/Brass/Aluminum/Titanium Parts, CNC Turning Mechanical Component

Customized processing according to drawings and samplesProvide design intentions, with professional team design drawings;

Basic Info

| Model NO. | SM-CTP-031 |

| Material | Stainless Steel |

| Application | Metal Recycling Machine, Metal Cutting Machine, Metal Straightening Machinery, Metal Spinning Machinery, Metal Processing Machinery Parts, Metal forging Machinery, Metal Engraving Machinery, Metal Drawing Machinery, Metal Coating Machinery, Metal Casting Machinery |

| Transport Package | Full Consideration of Practical Situation |

| Specification | Customization |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 5000piece/Year |

Product Description

Customized processing according to drawings and samplesProvide design intentions, with professional team design drawingsMajor products:

cnc machining; welding; cnc milling; precision machining; cnc manufacturing; cnc turning; machining process; machining parts; cnc machining center; milling machining; high speed machining; metal machining; custom machining; cnc machined parts; machining metal; precision machining company; cnc lathe; cnc fabrication; machining center; 5 axis machining; metal milling; lathe; machining manufacturing; cnc engineering; machining manufacturer; cnc precision; cnc machining services; micro machining; stainless steel machining; machining company; turning machining;

Service Principles: inexpensive, efficient and customer-oriented

Packaging & Delivery

Packaging Detail:

Anti-rust paper, small box and carton, full consideration of practical situation

Delivery Detail:

20 ~ 30 days for machining cnc parts

| Brand name | Showhum |

| Material available | 1.Stainless Steel:SS201, SS303, SS304, SS316, SS410, SS420 |

| 2.Steel:C45(K1045), C46(K1046),C20,etc. | |

| 3.Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58),C27200CuZn37), C28000(CuZn40),etc. | |

| 4.Bronze:C51000, C52100, C54400, etc. | |

| 5.Iron:1213, 12L14,1215,etc. | |

| 6.Aluminum:Al6061, Al6063, etc. | |

| 7.Carbon steel: C1006,C1010,C1018,C1022,C1035K,C1045,12L14,etc. | |

| 8.Alloy steel: SCM435,10B21, C10B33,etc. | |

| Surface treatment available | Zn-Plated,Ni-plated,Passivated,Tin-plated,Sandblast and Anodize,Polish,Electro Painting,Black Anodize,Plain,Chrome plated,Hot Deep Galvanize(H. D. G. ) etc. |

| Heat Treatment | Tempering,Hardening,Spheroidizing,Stress Relieving. |

| Standard | ISO,GB,DIN,JIS,ANSI,BSW |

| Manufacture Process | Heading,washer,assembly,Threading,Secondary machine,heat treatment,plating,Anti-slipping,Baking,QA Package,Shipping |

| Package | 1.Plastic Bags+Carton+Pallet2.according to customers requirements.3.Suitable for sea shipping and air shipping |

| Terms of payment | 30% deposit to confirm the order, left payment balance before shipping |

| Quality Warranty | Before shipping,the QC will test, and we confirm our goods will satisfy yr request of 100%, and have 18 month warranty |

| After sales service | we will follow up order for every customer and help solve problem before and after sales. |

| Equipment | Quantity | ||

| CNC machining centre | 17(contain 4,5axis processing centre) | ||

| CNC milling machine | 2 | ||

| CNC lathe | 7 | ||

| Cutting machine | 1 | ||

| Welding machine | 8 | ||

| CNC pipe bender | 2 | ||

| Blister packaging machine | 1 | ||

| Vibratory fininshing machine | 2 | ||

| Other machine | 5 | ||

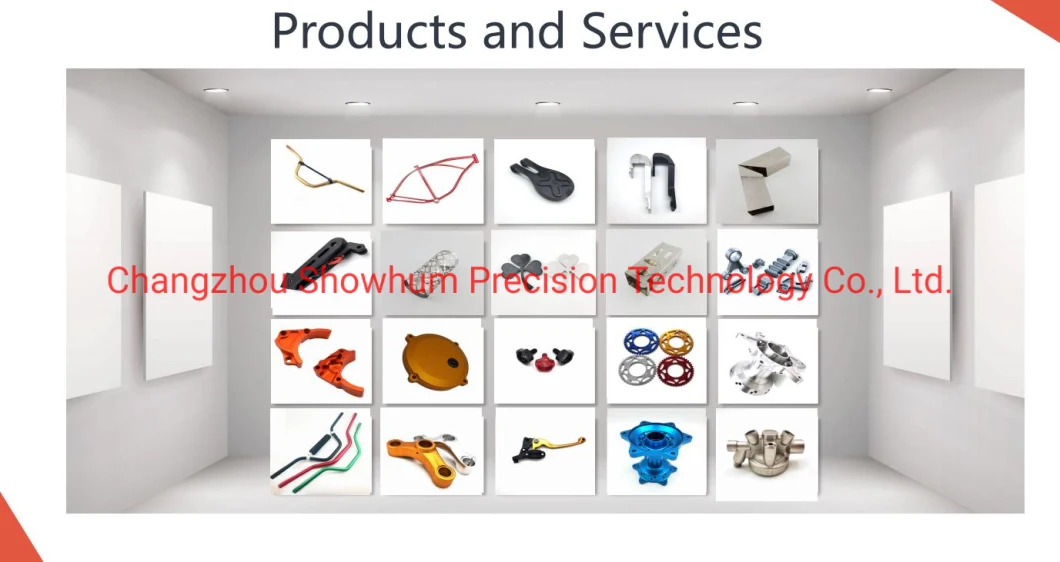

| Company Name | Changzhou Showhum Precision Technology | ||

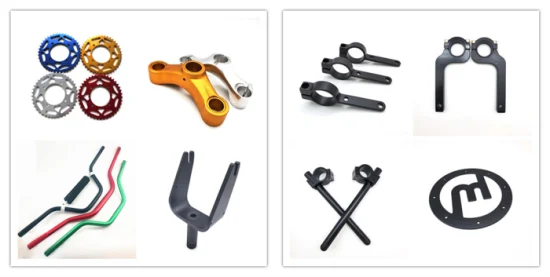

| Mainly Producing And Selling | Motorcycle Parts ,Auto Parts ,Forging Parts And Aluminum Alloy Welding Products,Water Cutting Parts | ||

| Testing Equipment | 3 D Coordinates Of The Instrument | ||

| Production Equipment | 5 Axis Machining Center, CNC Lathe | ||

| Welding Equipment | Argon Arc Welding Machine | ||

| Cutting Equipment | Laser Cutting .And Pipe Bending Machine, Punching Machine And So On. | ||

| Size and Design | According to the 2D or 3D drawing | ||

| Logo and Printing | According to the requirement | ||

| Small Order | Acceptable | ||

| OEM/ODM | Welcome | ||

| Logo & Printing | According to your requirements. | ||

| Sample and Charge | Sample charge based on the quantity | ||

| Mould open and charge | We have our own advanced mould machine, can supply best quality and lowest price mould. | ||

| Production Process | Get the Drawing--Produce the Sample-Send Sample to customer for confirmation--Book the order and arrange payment-Mass Production for the order--Trim and inspect the goods-packing and arrange shipment. | ||

| service idea | Our Company Has Won Wide Recognition And Praise For Our Stable Quality And Constant Innovation. We Are Committed To Sincerity, Specialization, Innovation And Service. We Sincerely Look Forward To Cooperating With Global Client Hand-in-hand And Making Our Products Become A World Known Brand. | ||

FAQ:

1

Q: Are you Factory or Trade company?

A: We are a company integrating industry and trade

2.

Q: How about the quality of your product?

A: 100% inspection during production

3.

Q: What kinds of machining service do you have?

A: Gringing, Machining, CNC milling and turning,CNC milling, CNC

metal, grinding, stamping, casting and forging parts,welding, assembly service.

4.

Q: What material of the product can you supply?

A: Carbon Steel, Alloy Steel, Stainless Steel, Brass, Copper,Plastic or according to your requirement.

5.

Q: What's the delivery time?

A: For products in stock, within 5-7 days after receiving your payment. For custom order, about 20-35 days after confirmed every details

6.

Q: What's your packing?

Anti-rust paper, small box and carton, full consideration of practical situation

7.

Q: What about the warranty?

A: We are very confident in our products, and we pack them very well with

PE Foam and carton box+wood pallet to make sure the goods in well protection.

8.How to order High Precision OEM and Customized Machining Parts for Industrial Machinery ?

* You send us drawing or sample

* We carry through project assessment

* We give you a design

* You think the design is ok

* We make the sample and send it to you

* You think the sample is good then place an order and pay us 50% deposit

* We start to make the product

Processing Method: custom medical precision parts high demand parts precision machining hardware

cnc machining, turning, milling, drilling, grinding, broaching, welding and assembly.

Service Principles:Cheap , Efficient and Customer-oriented

9.Do you provide customized Machining parts?

Yes. Customers give us drawings and specifications, and we will ma

If there's anything we can help, please feel free to contact with us.

We're sure your any inquiry or requirement will get prompt attention.

You may also like

Send inquiry

Send now