99.95% Graphite Crucible Molybdenum Material Tungsten Crucible for Vacuum Coating

Basic Info

| Model NO. | GTL-10-01-005 |

| Bulk Density | 1.71g/cm3-1.85g/cm3 |

| Transport Package | Plywood Cases |

| Specification | Customized |

| Trademark | Gotrays |

| Origin | Shandong, China |

| HS Code | 3801909000 |

| Production Capacity | 30000/Per Month |

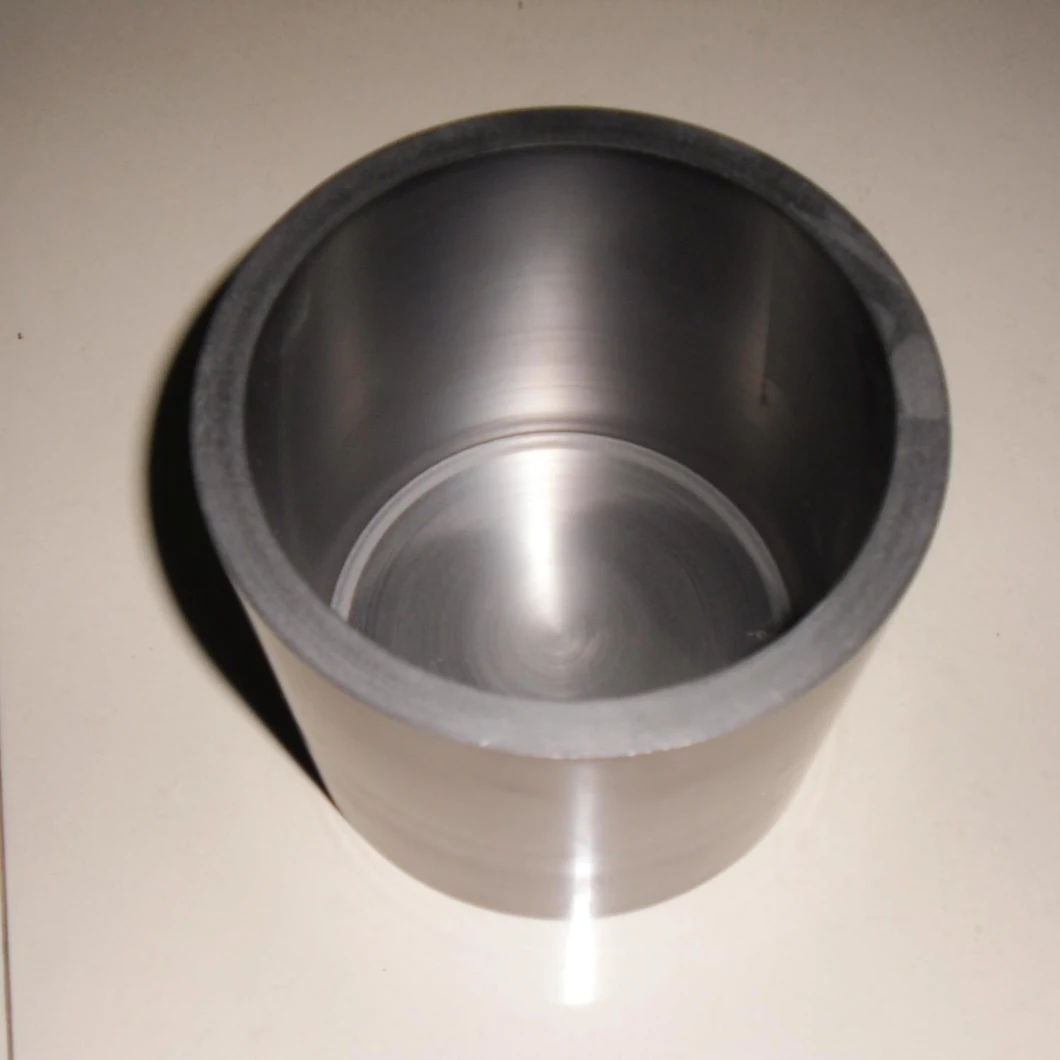

Product Description

Vacuum coating is a process of placing the material to be plated and the substrate to be plated in a vacuum chamber, heating the material to be plated in a certain way, making it evaporate or sublimate, and flying sputtering to the surface of the substrate to condense into a film.

Aluminum coated films are widely used as packing and decoration material. Vacuum aluminum evaporation coating, applied in the film production, is a process to form a composite film on the substrate by evaporating aluminum under vacuum condition. Graphite crucible is wearing part and its quality directly affects coated film quality and production cost.Graphite material is very important to vacuum aluminum.

Type | Average Grain Size (µm) | Bulk Density (g/cc) | Specific Resistivity (μΩ·m) | Flexural Strength (Mpa) | Compressive Strength (Mpa) | Shore Hardness | C.T.E(100-600ºC) ×10-6/ºC | Ash (ppm) |

| GT-CIP5F | 6 | ≥1.8 | ≤13.0 | ≥55.0 | ≥125.0 | ≥70.0 | ≤4.7 | ≤30 |

| GT-CIP5ST | 3 | ≥1.86 | ≤13.0 | ≥68.0 | ≥135.0 | ≥85.0 | ≤6.8 | ≤30 |

| GT-CIP1FR | 15 | ≥1.78 | ≤11.0 | ≥35.0 | ≥70.0 | ≥40.0 | ≤5.5 | ≤30 |

| GT-CIP1FV | 15 | ≥1.85 | ≤15.0 | ≥40.0 | ≥80.0 | ≥46.0 | ≤4.8 | ≤30 |

| GT-CIP1Q | 8 | ≥1.8 | ≤14.0 | ≥50.0 | ≥110.0 | ≥60.0 | ≤5.9 | ≤30 |

| GT-CIPRQ | 8 | ≥1.85 | ≤14.0 | ≥58.0 | ≥130.0 | ≥68.0 | ≤5.9 | ≤30 |

| GT-CIP1RB | 6 | ≥1.89 | ≤14.0 | ≥68.0 | ≥150.0 | ≥70.0 | ≤5.9 | ≤30 |

| GT-CIP4SX | 20 | ≥1.80 | ≤13.0 | ≥45.0 | ≥90.0 | ≥60.0 | ≤4.7 | ≤30 |

| GT-1RV | 10 | ≥1.67 | ≤15.0 | ≥36.0 | ≥78.0 | ≥58.0 | ≤5.8 | ≤30 |

| GT-2C | 15 | ≥1.72 | ≤15.0 | ≥50.0 | ≥100.0 | ≥57.0 | ≤5.8 | ≤30 |

| GT-3S | 12 | ≥1.78 | ≤17.0 | ≥52.0 | ≥102.0 | ≥60.0 | ≤6.0 | ≤30 |

Zibo Gotrays' Focused Applications

- Graphite crucibles could be continuously used for 25~48 cycles based on different aluminum coating process and different quality requirements.

Our Advantages

Zibo Gotrays' Advantages :

- Anti-oxidation, anti-abrasion, long service life.

- Customize: Produced according to Customers' Needs.

- Professional Design Ability according to Application.

- Complete Supply Chain System Assuring Competitive Product Price.

- Globally 7x24 Sales and Technical Services, Fast Response for Delivery.

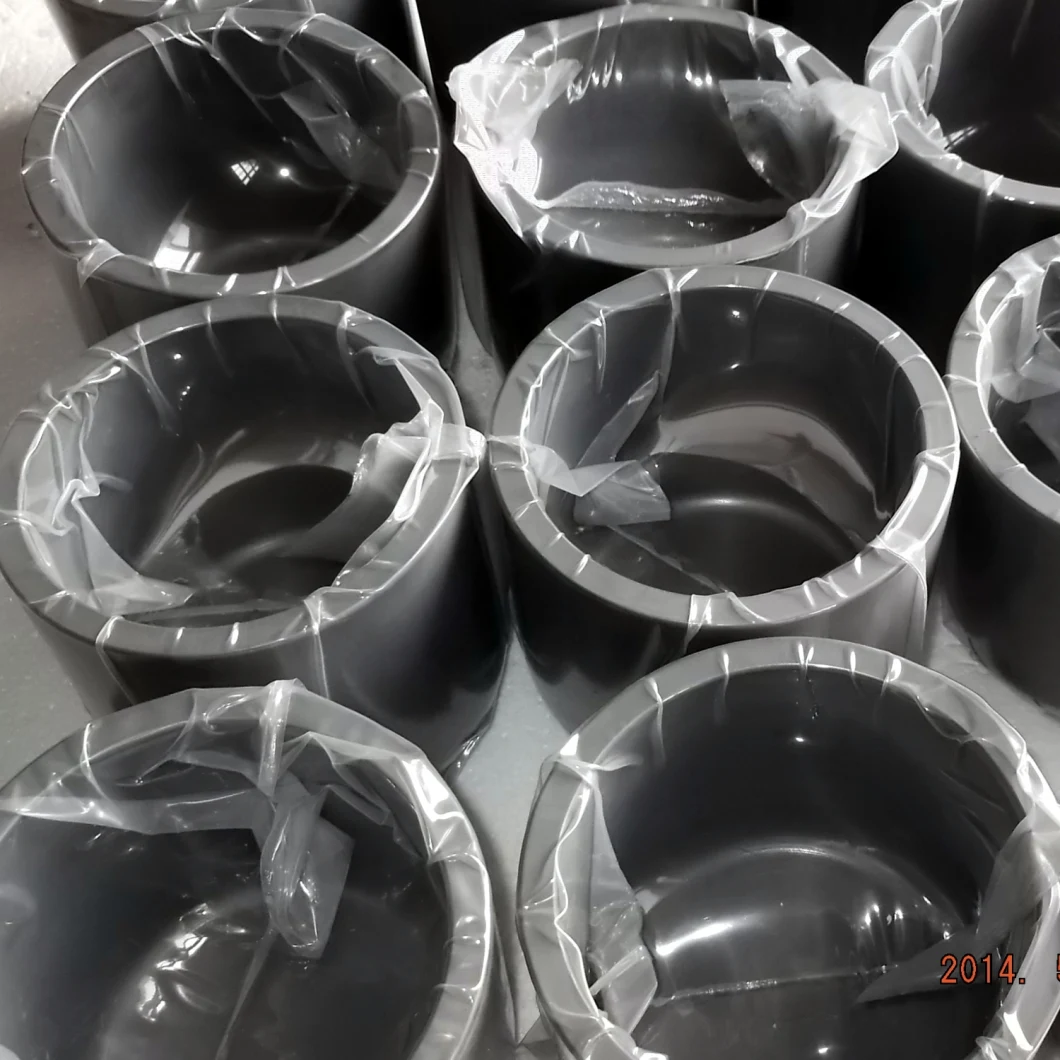

Detailed Photos

Company Profile

Certifications

Packaging & Shipping