Tungsten Molybdenum Alloy Crucible, Sapphire Molybdenum Crucible&High Temperature Molybdenum Crucible

Customized High Temperature Molybdenum Alloy MoLa Boats&TZM alloy Boats Supplier MoLa boats information: 1) Surface:alka;

Basic Info

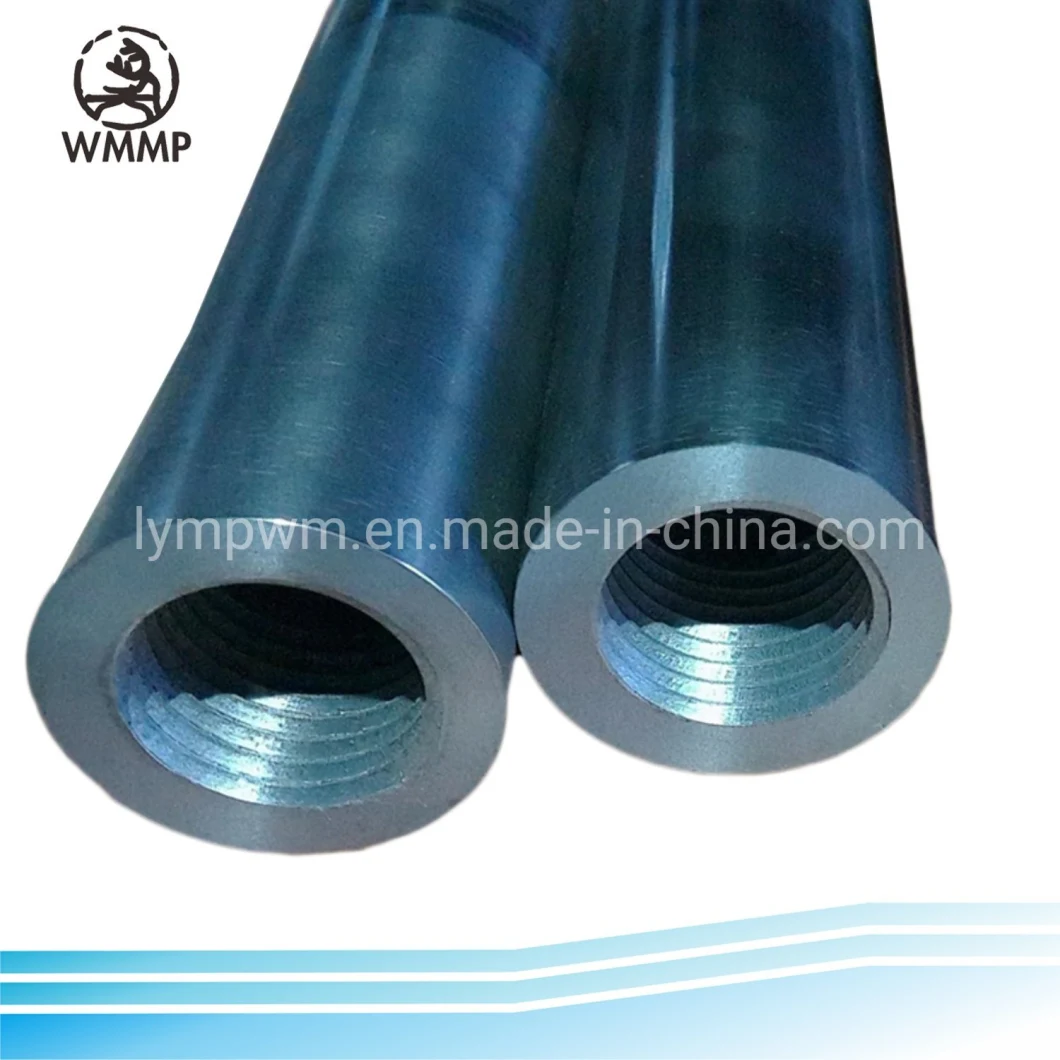

| Model NO. | Mo1 tube |

| Transport Package | Standard Exported Plywood Case/Wooden Packing |

| Specification | Customized |

| Trademark | WMMP |

| Origin | China |

| HS Code | 8102950000 |

| Production Capacity | 5000kg/Month |

Product Description

Customized High Temperature Molybdenum Alloy MoLa Boats&TZM alloy Boats SupplierMoLa boats information:

1) Surface:alkali washed/sandblasting and polished Or we can supply as the customers' need

2) Density: about 10.2g/cm3

3) Grade: Mo-1,TZM&MoLa boats

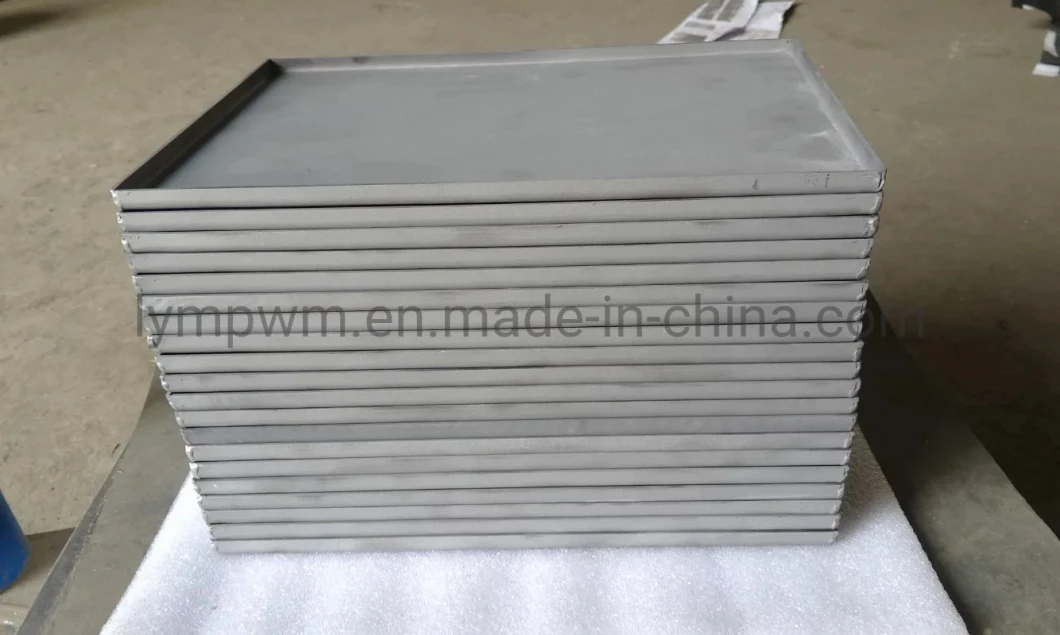

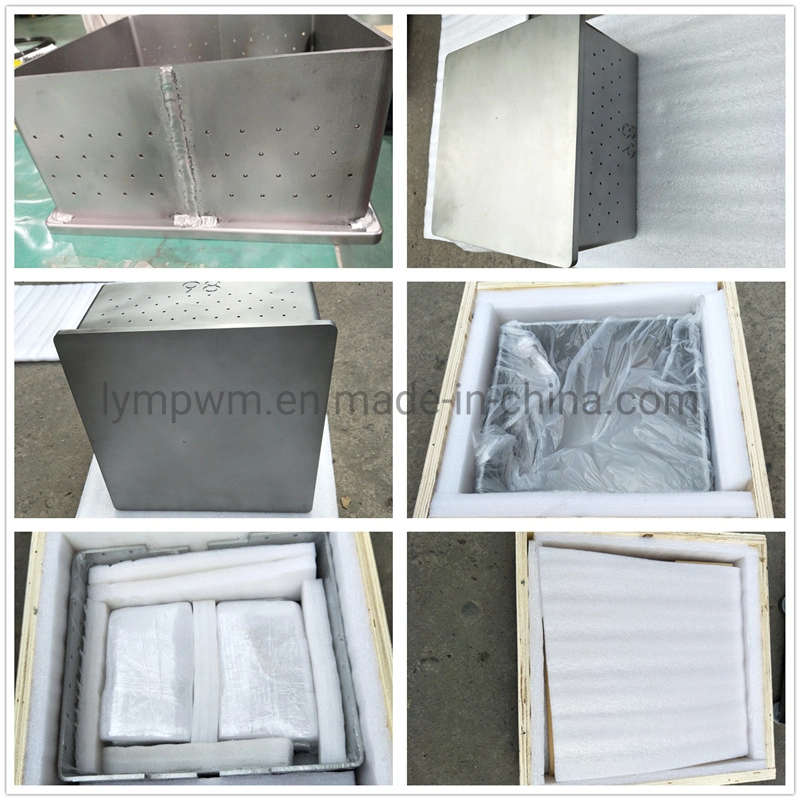

4) Molybdenum boats type: Joint, Riveted,fold, weld

5) With or without drilling holes, according to drawing

Molybdenum boats size information:

| Delivery condition | Dimension(mm) | Tolerance(mm) | ||

| Diameter(mm) Height(mm) | Diameter(mm) | Height(mm) | ||

| Sintering | 10-500mm 10-600mm | +/-5 | +/-5 | |

| Forging | 10-130mm 10-200mm | +/-1 | +/-2 | |

Pure molybdenum boat size information for PVD Vacuum Coating

Thickness(mm) | width(mm) | length(mm) | groove length(mm) | Boat depth(mm) |

0.3 | 8 | 100 | 60 | <2.0 |

0.2 | 10 | 100 | 60 | <2.0 |

0.3 | 10 | 100 | 60 | <2.0 |

0.5 | 10 | 100 | 60 | <2.0 |

0.3 | 12 | 100 | 60 | <2.0 |

0.5 | 12 | 100 | 60 | <2.0 |

0.2 | 15 | 100 | 60 | <2.0 |

0.3 | 15 | 100 | 60 | <2.0 |

0.5 | 15 | 100 | 60 | <2.0 |

0.3 | 13 | 50 | 25 | <2.0 |

Other molybdenum boats need:

If you have special requirement, we recommend you to choose TZM, and high temperature MoLa boats.

TZM: we add titanium and zirconium to strengthen the microstructure of pure molybdenum. Mo-Ti solid solution and

Ti-Zr carbides ensure that optimum strengths are achieved at temperatures up to 1400° C

MLa: Small quantities of lanthanum oxide particles (0.3 or 0.7 percent) give the molybdenum a so-called stacked fiber structure. This special microstructure is stable at up to 2000° C.

Our TZM(Titanium-Zirconium-Molybdenum)Alloy Information:

TZM Performance:TZM has twice the strength of pure moly at temperatures over 1300° C.The recrystallization temperature of TZM is approximately 250° C higher than moly and it offers better weldability.TZM Molybdenum is manufactured by either P/M or Arc Cast technologies and is of great utility due to its high strength/high temperature applications, especially above 2000'F.TZM Molybdenum has a higher recrystallization temperature, higher strength, hardness and good ductility at room and elevated temperatures than unalloyed Molybdenum. In addition, TZM exhibits good thermal conductivity, low vapor pressure, and good corrosion resistance and is machinable.

TZM Alloy application:1)TZM is widely used in the aerospace, aviation and other industries. It could be used as nozzle material, valve body, gas piping materials, tubes in the gate material, die casting molds, extrusion dies and high temperature furnace heating element and heat shield etc.

2)Used for seamless stainless tubes of stainless,aloy steel and high temperature alloy.

Thermal and Electrical Properties of TZM Alloy (Ti0.5/Zr0.1)

Properties | Coefficient of Thermal Expansion /K-1 (20~100ºC) | Thermal Conductivity W/m·K | Max Working Temperature in air ºC | Electrical Conductivity Ω·m |

Data | 5.3X10-6 | 126 | 400 | (5.3~5.5)X10-8 |

Advantages of TZM compared compared to pure molybdenum:

1)Above 1100 centigrade tensile strength is about twice that of unalloyed molybdenum2)Better creep resistance3)Higher recrystallization temperature4)Better welding properties

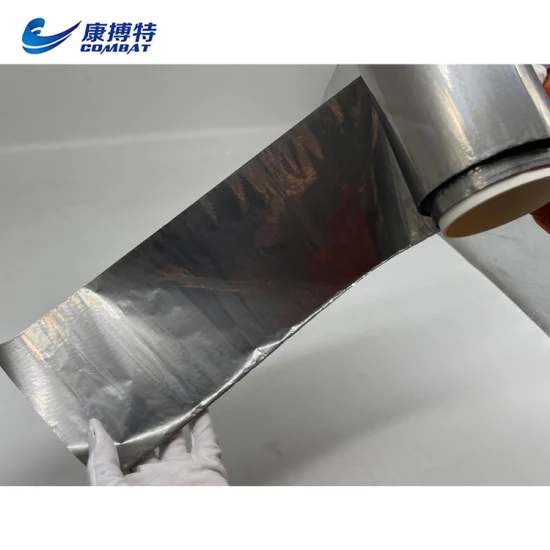

Our molybdenum alloy boat relevant products and packing photoes,hope you are interested in them:

More Tungsten Molybdenum Crucible&Their alloy crucible photoes

You may also like

Send inquiry

Send now